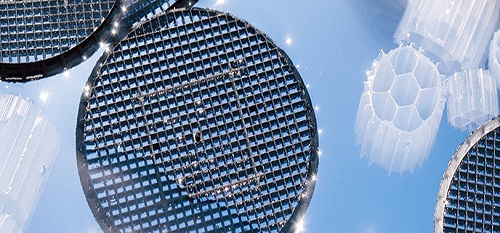

MBBR Technology

In the MBBR bio-film technology the bio-film grows protected within engineered plastic carriers:-

MBBR Technology [Moving Bed Bio-film Reactor]

In the MBBR bio-film technology the bio-film grows protected within engineered plastic carriers, which are carefully designed with high internal surface area.

1. These Bio-film carriers are suspended and thoroughly mixed throughout the water phase.

2. This technology it is possible to handle extremely high loading conditions without any problems of clogging, and treat Industrial and municipal wastewater on a relatively small Footprint.

3. MBBR bio-film technology is efficient.

4. Compact and easy to operate.

5. It can be an excellent solution as a stand-alone process.